Augmented Labyrinth Brush Seals

Reduce Clearances, Improve Efficiency

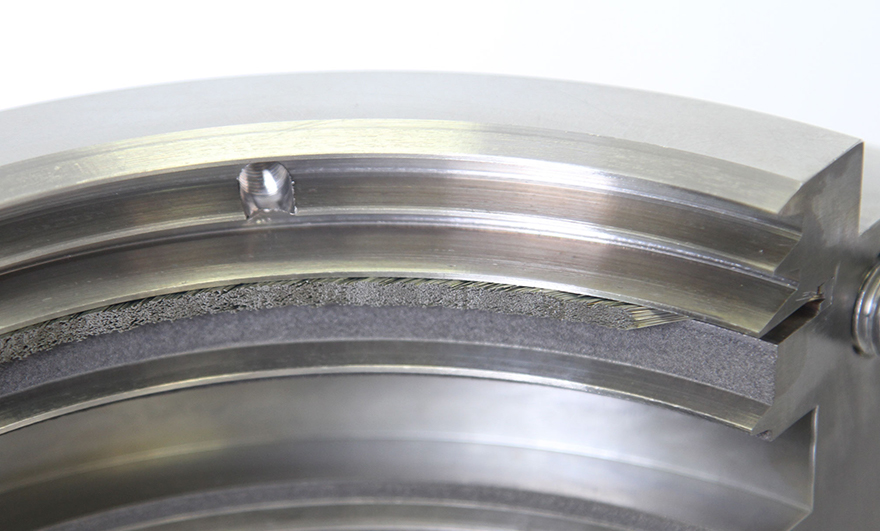

Augmenting labyrinth seals with brush seals, or installing complete replacement labyrinths with brush seals, is a simple and effective approach to reducing clearances and eliminating problems from shaft contact wear.

The Importance of Compliance

Over time, labyrinth seal clearances are compromised through erosion and material removal, which can stem from factors such as rotor-stator interaction (due to high imbalance loading) or transient excursions (due to asymmetric thermal growth between the rotor and casing). In addition, since labyrinth seals are rigid geometry seals and are not capable of bending to accommodate rotor excursions, design clearances are engineered to account for all phenomena affecting clearance closures in the machine.

The brush seal’s compliancy – its ability to bend – allows sealing clearances to be significantly reduced, thus increasing machine efficiency and power.

Retrofit Capability

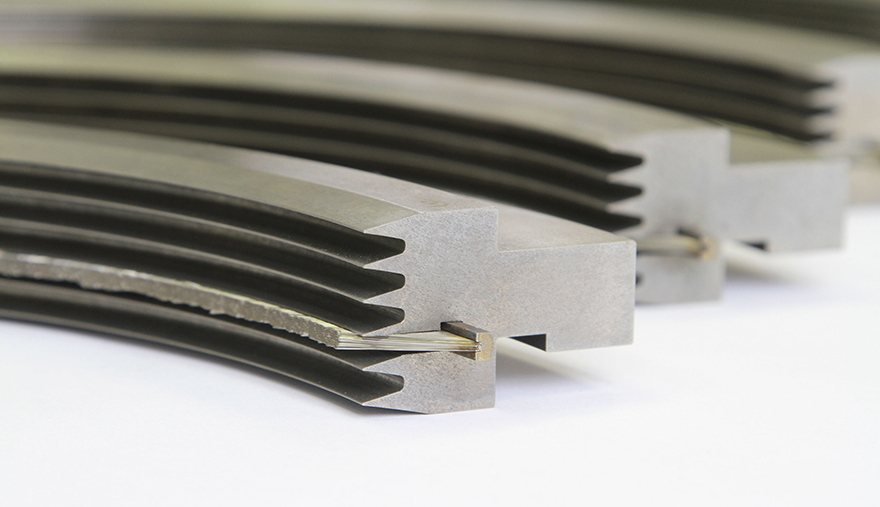

The low profile of the Bearings Plus bristle strip provides a simple and cost-effective integration with an existing labyrinth seal. We typically utilize the existing labyrinth blades and teeth to create a back plate. Wire EDM technology ensures precise and reliable clearances for the labyrinth’s augmentation to accept the brush seal.

Bearings Plus has upgraded a large number of equipment with augmented labyrinth seals, including process steam turbines, centrifugal compressors, and turboexpanders.

Advantages

- Reduce initial leakage by 50% compared to straight labyrinth seals, or by 30% compared to interlocking labyrinth seals

- Eliminate steam leaks and the safety hazards associated with high temperatures and toxic gases

- Reduce condenser capacity and space requirements in new steam turbines

- Require less axial space than labyrinths

- Easily installed and field serviceable in a variety of sealing environments

- Allow a “wear-in” to minimal clearance through flexible sealing mechanism

- Standard components for cost-effectiveness and timely shipment

- Can be field fitted to undersized shafts, eliminating the need to weld or coat worn rotors