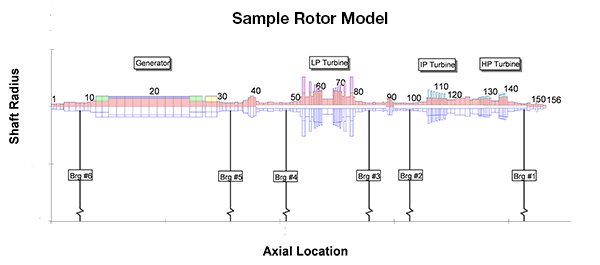

Rotordynamic Analysis

Industry-Leading Knowledge and Tools

Along with the rotor, the bearings and seals are the most influential components in rotating equipment vibrations. With our deep understanding of bearings and seals, Bearings Plus can develop rotor models, characterize unbalance and destabilizing forces, and recommend solutions to address high vibration and stability issues. The end result: improved overall performance and service life for the equipment.

Our industry-leading analytical tools include transfer matrix, polynomial transfer matrix and finite element–based rotordynamic analysis tools. The accuracy of our analyses and predictions allows us to optimize the dynamic characteristics of bearings and seals for your individual operating system to ensure optimal performance, whether it is for a new bearing design or repair on an existing design.

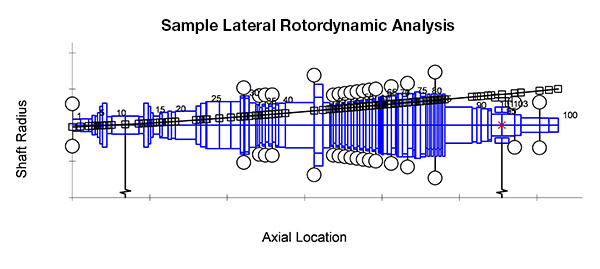

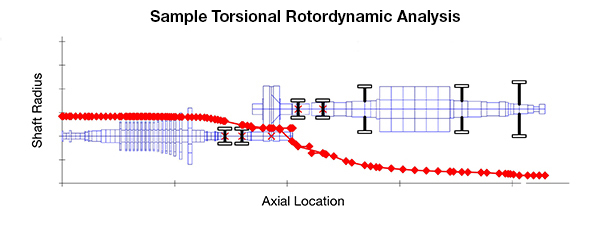

Torsional, Axial and Lateral Analysis

Torsional, axial and lateral vibrations can each affect the efficiency and reliability of rotating equipment. Torsional vibration is an angular vibration, or twisting, of the shaft. Axial vibration occurs along the axis of rotation. Lateral vibration occurs perpendicular to the axis – side to side or up and down or both.

Upon receipt of the relevant information, our engineers build a rotor model and analyze the bearings and seals using proprietary codes. The customer receives a comprehensive report of the findings, based on the type and scope of analysis performed.

Lateral Rotordynamic Analysis

- Undamped critical speed (UCS) analysis

- Damped critical speed analysis

- Eigenvalue analysis (critical speeds, mode shapes)

- Unbalance response analysis

- API stability analysis (level I and II)

- Bearing and seal optimization

- ISFD optimization, if needed

- Brush seal contact-induced stability and unbalance analysis, if needed

Torsional Rotordynamic Analysis

- Torsional natural frequencies

- Eigenvalue analysis (critical speeds, mode shapes)

- Damped torque or stress response analysis, if needed

- Transient analysis for start-up or short circuit analysis for motor or generator trains

- Transient torsional stress analysis on critical points (e.g., coupling, rotor)

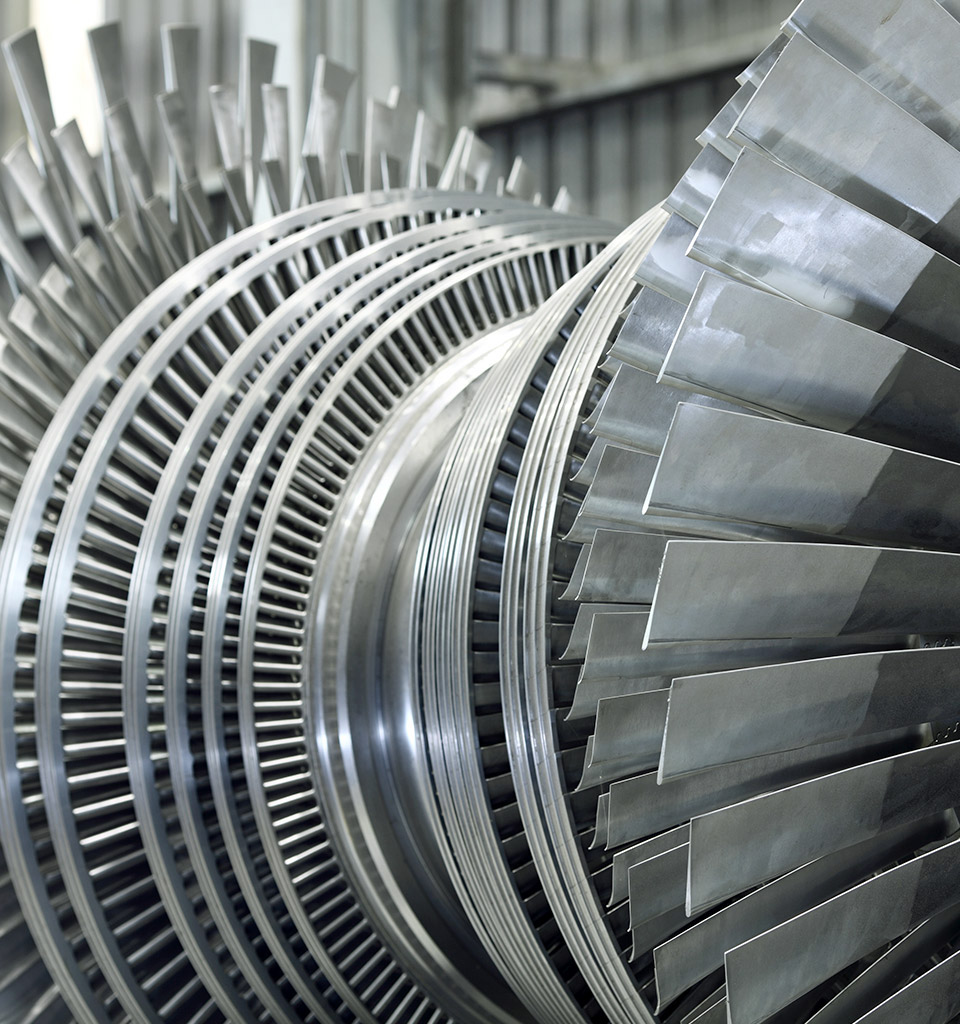

Typical Applications

- Compressors

- Steam and gas turbines

- Expanders (radial turbines)

- Turbochargers

- Microturbines

- Motors

- Generators

- Pumps

- Gearboxes

- Propulsion shafts

- Blowers

- Fans

Downloads

- Vibrations and Eccentricity Measurements Combined with Rotordynamic Analysis on a Six Bearing Turbine Generator (Proceedings of the 27th Turbomachinery Symposium, 1998)

- Rotordynamic Analysis Information Sheet