Flexure Pivot Tilt Pad Journal Bearings

Lasting Tilt Pad Performance

Flexure Pivot® tilt pad journal bearings are a leading bearing solution for high-load, high-speed, small-diameter shafts.

They achieve low cross-coupling and high stability while eliminating pivot wear, high contact stresses and pad flutter.

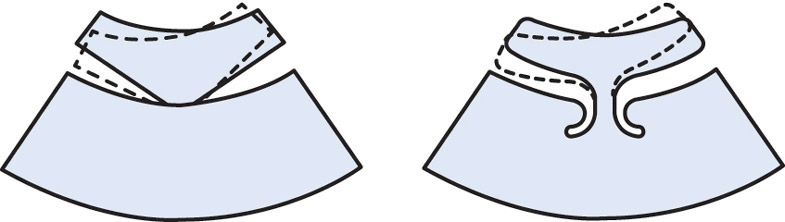

The Flexure Pivot tilt pad moves through flexure and rotation of the center post, instead of a rocking or sliding motion. Doing so eliminates pivot wear and contact stresses common on high load, high speed machines. This prevents degradation in performance with time, maintains the desired bearing preload, and provides a narrower spread in the stiffness and damping coefficients.

Optimal Rotordynamic Characteristics

The integral pad-pivot-retainer design also minimizes manufacturing tolerance stack-up, a critical design parameter that has a direct impact on the rotor’s stability, critical speed, and synchronous response characteristics.

The rotational stiffness of the pivot is selected such that the destabilizing cross-coupled stiffness coefficients are negligible, ensuring optimal rotordynamic characteristics. The rotational stiffness also increases the pad’s natural frequency and eliminates pad flutter and spragging often encountered on the unloaded pads in conventional tilt pad bearings.

Retrofit Capability

The Flexure Pivot journal bearing offers the performance of a tilt pad bearing with the simplicity of a sleeve bearing. Installation is easy and the pads never need adjustment.

Available with a very small wall thickness, the Flexure Pivot journal bearing can, in some cases, replace conventional sleeve bearings without any requirement for housing modifications.

The advanced techniques used in the manufacture of Flexure Pivot tilt pad bearings also make them a good choice for retrofitting small and miniature fluid film bearings, as well as rolling element bearings.

Technical Data

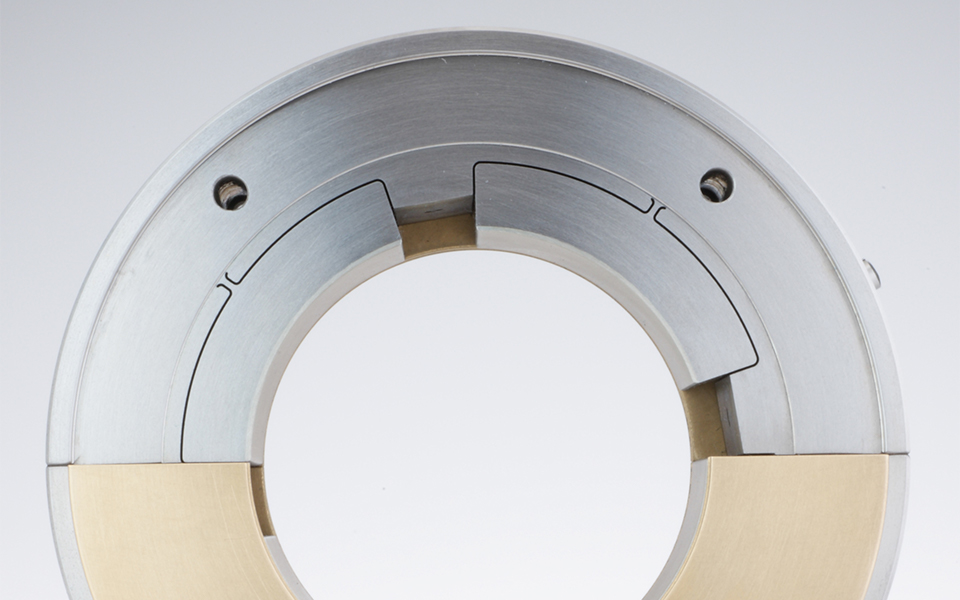

- One-piece or split configuration

- Typical sizes from 7mm (0.3″) to 150 mm (6″)

- Compact design for retrofit

- Surface speeds up to 125 m/sec (410 ft/sec)

- Unit loads up to 3.5 MPa (500 psi)

- Tri-metal material option

- Instrumentation options – RTD or thermocouple temperature sensors; optional provision for proximity probes

Typical Applications

- Integrally geared air/process compressors

- Refrigeration compressors

- Integrally geared pumps

- Micro gas turbines

- Expanders

- Gearboxes

Downloads

- Flexure Pivot Bearings Information Sheet

- Experience in the Use of Flexure Pivot Tilt Pad Bearings in Boiler Feedwater Pumps

- Application of High Speed and High Efficiency Hydrogen Turboexpanders in Refinery Service

- Design, Analysis and Testing of High Performance Bearings in a High Speed Integrally Geared Compressor

- A Flexible Pad Bearing System for a High Speed Centrifugal Compressor

- Journal Bearing Inquiry Sheet

Related Case Study

Long-term Solution to Vibrations

Over a 13-year span, a major South American oil company’s maintenance department fought recurring high vibrations in three gas reinjection compressor trains. Based on a thorough analysis of the compressors and an inspection of damaged components, Bearings Plus proposed a two-part solution: Flexure Pivot journal bearings and an integral squeeze film damper.