Squeeze Film Dampers

Squeeze film dampers are used to shift critical speeds and/or to increase the dynamic stability of a rotor/bearing system.

One of the key features of a squeeze film damper is the introduction of support flexibility and damping in the bearing/support structure. This translates to lower transmitted forces and longer bearing life, particularly for machinery designed to operate at supercritical speeds.

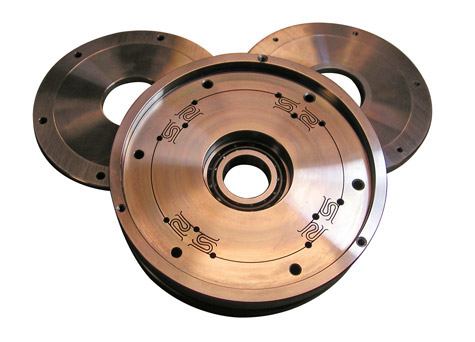

Bearings Plus offers a sophisticated integral squeeze film damper – our ISFD® technology – to provide a highly accurate yet simple solution for new and retrofit installations requiring squeeze film dampers.

The ISFD design, optimized with finite element methods and manufactured by wire EDM, provides precisely controlled stiffness and damping. It maximizes energy dissipation at the bearing location and significantly improves system stability.

ISFD Technology

This unique damper design provides:

- Precise stiffness and damping to match rotordynamic requirements

- Constant stiffness and damping over a wide range of motion

- Minimal space requirements

- Shaft-centering ability

Unlike O-ring dampers, the ISFD design takes high radial loads and offers linear stiffness unaffected by temperature or age. Unlike squirrel cage dampers, the ISFD maintains parallelism between the damper journal and housing.

View the Animation

Watch how ISFD technology uses a combination of custom-engineered springs and a squeeze film damper land to provide precise stiffness and damping to tune the rotor’s critical speeds and mode shapes.

ISFD Design Versatility

ISFD technology can be integrated into a wide range of journal bearing styles:

- Flexure Pivot® bearings

- Rocker back bearings

- Ball and socket bearings

- Sleeve bearings

- Elastomer bearings

- Rolling element bearings

In every instance, the damper is optimized for the specific application through rotordynamic analysis, significantly improving system stability and offering accurate predictability.

The space-saving design allows for drop-in replacement without modifications to the bearing housing.

Split configuration is available for compliance with API specifications dictating split bearings configuration.

ISFD Technology with a Ball Bearing

ISFD Technology with Elastomer

Typical Applications

- Integrally geared compressors

- Centrifugal compressors

- Steam turbines

- Gas turbines

- Turbo-expanders

- Radial turbines

- Supercritical CO2 power turbines

- Generators

- Motors

- Overhung process equipment