Case Study

Integral Squeeze Film Damper Reduces Vibrations, Increases Production

The Dow Chemical Company operation in Deer Park, Texas, creates specialty chemicals for paint, detergent, floor care, adhesives and sealants, automotive coatings, acrylic plastics, personal care products, water purification and other diverse markets. The facility covers 700 acres along the Houston Ship Channel and relies on a fleet of rotating equipment to meet production demands.

When an overhung blower that was part of the sulfuric acid unit required shutdown every three to four months for cleaning and rebalancing, Rotating Equipment and Vibration Engineer Allan Mathis and Mechanical Technologist Bart Theriot took action.

Product buildup on the machine’s impeller was leading to a mass imbalance and high synchronous vibrations that, if not addressed, could cause catastrophic bearing machine failure. So, every three to four months, the machine was shut down for four days (96 hours) for maintenance. To eliminate this frequent cleaning and rebalancing, Mathis sought the expertise of Bearings Plus®. The critical speed was to be dampened, the dynamic bearing load reduced and the vibration response improved.

Bearings Plus proposed installing an integral squeeze film damper on the impeller end of the shaft to reduce the vibration amplitudes, make the machine less sensitive to imbalance and shift the critical speeds. This ISFD® technology, which integrates the damper and bearing, provides highly engineered stiffness and damping to change rotordynamic behavior. For the blower at Deer Park, the ISFD technology was paired with a low-profile Flexure Pivot® tilt pad bearing (Figure 1).

Rotordynamic Analysis Predicts Performance

To test the solution prior to installation, Bearings Plus and Dow partnered on a lateral rotordynamic analysis. Baseline rotor models without the integral squeeze film damper were created first to confirm the data collected from the models against field vibration data.

The damped eigenvalue map of the first forward and backward rotor modes, the stability analysis, the synchronous response to imbalance, and the dynamic bearing loads on the models all matched field data.

With confidence in the rotordynamic modeling established through the baseline analysis, Bearings Plus modeled the rotor performance with the proposed ISFD technology/Flexure Pivot bearing on the impeller end. A support stiffness of 250,000 lb/in was selected so that the radial deflection at the impeller end bearing (for 2,038 lbs of bearing reaction force) was approximately 8 mil. At this stiffness, the optimum damping value for the first mode was approximately 2,300 lb-s/in, as shown in Figure 2.

Using this combination of stiffness and damping coefficients for the ISFD solution, the damped eigenvalue analysis showed the subsynchronous logarithmic decrement (log dec, or stability margin) for the first forward whirl mode eigenvalue to be more than three times the log dec for the original 5-pad tilt pad bearing configuration. The ISFD solution also created less of a bending mode and more of a rigid body mode, reducing alternating stresses on the shaft.

Furthermore, the analysis calculated the rotordynamic response to rotor imbalance. As shown in Figure 3, the ISFD solution eliminated the critical speed peak in the machine’s vibration response at both the impeller and coupling end of the shaft. The reduction in dynamic bearing loads with the ISFD technology is shown in Figure 4.

By all indications, the ISFD technology provided a more robust system that was less sensitive to imbalance loading from product buildup on the impeller, which would increase the mean time between maintenance.

Increasing Production in the Field

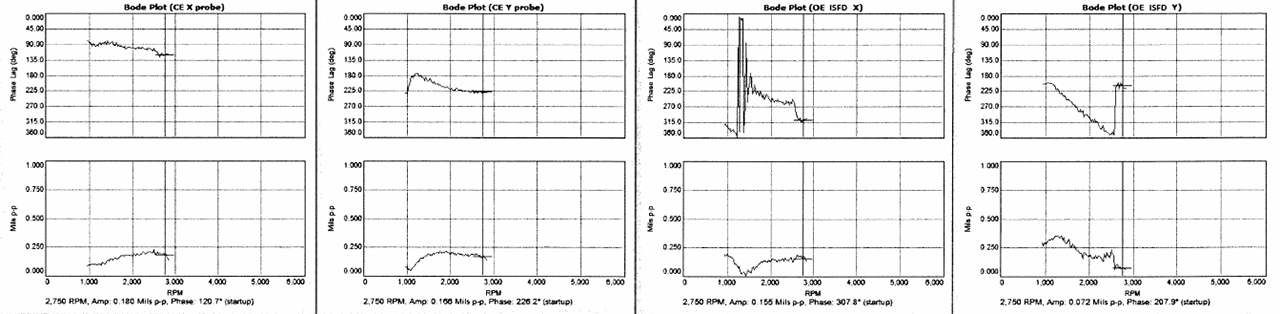

In 2013, the ISFD solution was installed in the field. Dow tested the bearing with 31 gm imbalance (at 17″ radius) to get a forced response (Figure 5). “The system responded like a champ,” said Mathis. The ISFD technology reduced the synchronous vibration response on both the impeller and the coupling end. In regular operation, the first critical speed was completely dampened.

In contrast, the original bearings would experience vibrations of up to 5-6 mils when process carryover occurred and product built up on the impeller. While the ISFD technology will not prevent product buildup or the resulting imbalance, the optimized damping absorbs the energy of the vibrations to allow continued operation without damage to the bearing.

With more than three years in operation on the original blower and two more bearings installed on sister blowers at Dow’s Deer Park operation without a shutdown, ISFD technology has saved Dow around 1,200 hours of production and eliminated the associated maintenance cost of opening and closing the equipment, hydro blasting and field balancing.

Figure 5: ISFD solution’s response to field test with 31 gm imbalance