Bearing Damage Resources

Bearing Damage Index

The vast majority of fluid film bearings give excellent service over long periods of time. When bearings do suffer damage, the cause may be obscure. Often, damage is the result of several failure modes combined.

The bearings themselves are often blamed, but while faulty design or manufacture of the bearings may be responsible, the cause is more frequently external to the bearing.

Identify Problems – and Solutions

This Bearing Damage Index is intended to inform operators regarding the likely causes of bearing damage and to identify possible responses and solutions.*

The final decision on how to address bearing damage must be based on the nature and severity of the damage and on the significance of the type of damage. As each application’s operating conditions are unique, decisions should be made in partnership with qualified engineers.

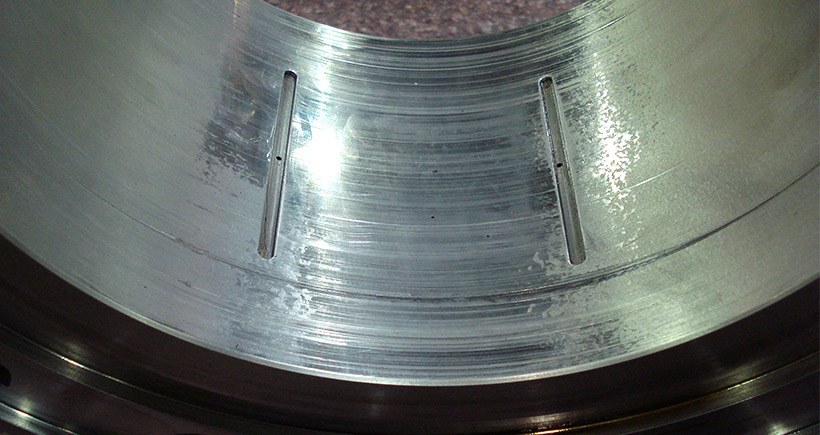

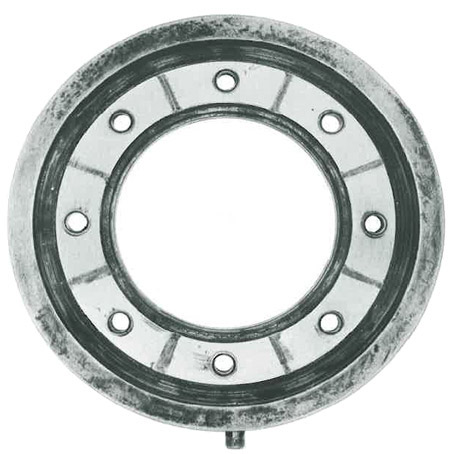

Types of Bearing Damage

*This information is given in good faith but no guarantee is given or implied in respect of such information. Please see our complete Terms of Use.

Additional Resources

- Hydrodynamic Bearing Damage and Remediation of Contributing Factors in Rotating Machinery (9th EDF/Pprime [LMS] Poitiers Workshop, 2010)

- Fluid Film Bearing Fundamentals and Failure Analysis (Proceedings of the 20th Turbomachinery Symposium, 1991)

- Plain Bearing Damage (Proceedings of the 4th Turbomachinery Symposium, 1976)

Downloads

Bearing Failure Analysis

Bearings Plus provides expert technical support to help pinpoint the cause and mode of failure. Put our analytical tools and expertise to work to identify and address your machine’s challenges.

Repairs and Replacements

Bearings Plus is a service-oriented shop with extensive bearing repair capabilities. Our state-of-the-art equipment, specialized measurement machines and robust quality inspections ensure the work is done with precision, as well as speed.