System Optimization

Bearings play a critical role in rotating equipment reliability, efficiency and life.

They control the rotor position, balance forces and provide damping for the system. Having the right bearing for your application and operating conditions is therefore essential to the successful long-term operation of your equipment. Likewise, seals and dampers can significantly affect system stability and efficiency.

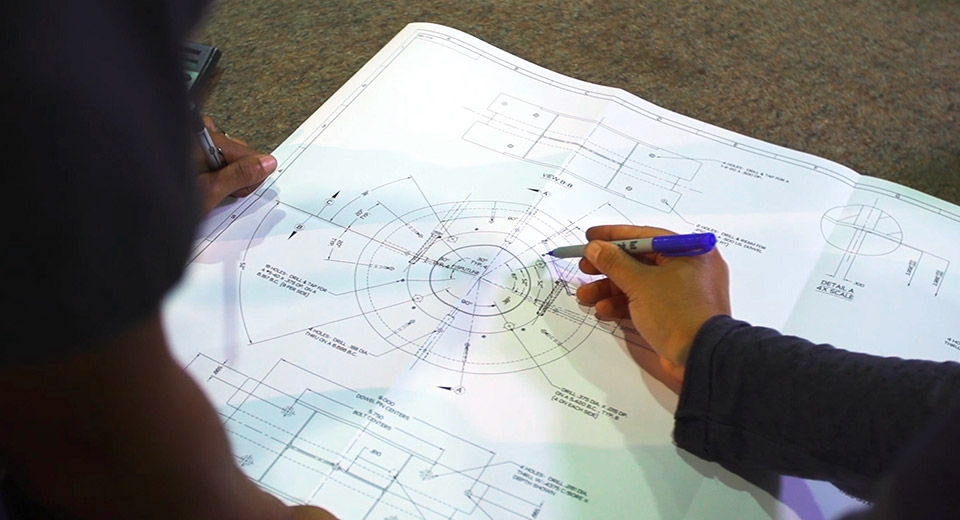

Bearings Plus applies 25 years of experience along with proven design codes and advanced analytical techniques to optimize bearing, damper and seal configurations and enhance the rotordynamic characteristics of your system.

Complete Rotor Modeling

Our specialists use rotor modeling and a full evaluation of the operating conditions to simulate critical speeds, rotor modes and unbalance response, among other characteristics, with various bearing and seal configurations.

Cross-coupling effects and potentially destabilizing seal forces and stage forces are examined together to get a complete picture of system performance. Specialized damper solutions are incorporated as needed, with optimum stiffness and damping coefficients precisely calculated for the application.

As a result, you get reliable performance predictions and solutions you can trust to keep your crucial equipment running.

Designed for Performance Enhancement

In addition, through analyses and optimization, Bearings Plus can design bearings, dampers and seals to lower power losses, increase load capacity, lower vibration amplitudes, lessen sensitivity to imbalance, accommodate misalignment, or achieve other operating requirements for your equipment.

Talk to Bearings Plus today about advancing your rotating equipment performance.

System Optimization Services & Solutions

Advanced Rotordynamic Analysis

Along with the rotor, the bearings and seals are the most influential components in rotating equipment vibrations. With our deep understanding of bearings and seals, Bearings Plus can develop rotor models, characterize unbalance and destabilizing forces, and recommend solutions to address high vibration and stability issues. The end result: improved overall performance and service life for the equipment.

Bearing Failure Analysis

Bearings are among the most critical components for the safe and reliable operation of rotating machinery. While fluid film bearings are designed for infinite life under design conditions, they are also designed to be a sacrificial component in case of upset conditions. Therefore, any issues with the machine will likely manifest at the bearings.

Leading Vibration Solution

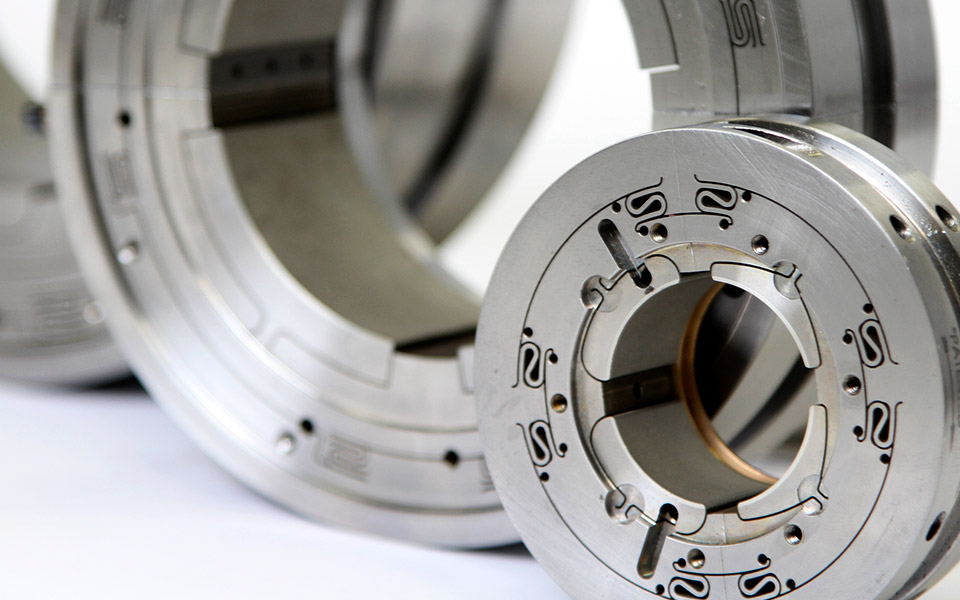

To shift critical speeds and increase the dynamic stability of the rotor/bearing system, Bearings Plus offers patented ISFD® technology. Suitable for new and retrofit installations, this unique damper design provides a lasting solution to vibrations.

Long List of Upgrade Successes

Bearings Plus provides replacements and upgrades for both fixed profile and tilt pad bearings, and offers proprietary product solutions to improve stability, control vibrations, eliminate pivot wear and address a myriad of other challenges.

BPI has upgraded bearings on numerous integrally geared compressors, multi-stage compressors, blowers, fans, steam and gas turbines, expanders, motors, generators, pumps and gearboxes. Our past successes speak for themselves.