Case Study

ISFD® Technology Eliminates Subsynchronous Vibrations on Steam Turbine to Achieve Full Power Output

Doosan Škoda Power has more than a century’s experience manufacturing steam turbines and is investing in research and development to be an international leader in the delivery of advanced clean energy technologies. Among the company’s innovative solutions are systems that utilize waste heat and leverage cycle efficiencies.

For a power generation customer in Scandinavia, Doosan Škoda Power engineered a 46 MW steam turbine as part of a combined cycle system for generation of electricity as well as heat recovery. During the initial commissioning process, however, the turbine experienced rotor instability that prevented the drive train from operating at full load. High subsynchronous vibrations forced a trip in turbine operation at just 27 MW versus the rated 46 MW.

Changes to the bearing clearances and configurations mitigated the vibrations but were not able to eliminate them completely. Doosan Škoda Power contacted Bearings Plus for a damper solution.

Bearings Plus performed a system-level rotordynamic assessment of the turbine, which evaluates the rotor, bearings and seals, and confirmed the cause of the vibrations to be a flexible rotor (caused by the large span between the bearings) combined with steam whirl forces in secondary sealing locations.

For a solution, Bearings Plus suggested soft-mounting the rotor system on tilt pad journal (TPJ) bearings with ISFD® technology. The patented integral squeeze film damper design significantly improved the turbine’s rotordynamic stability, eliminating the subsynchronous vibrations and significantly reducing the amplification factor at the critical speed. Ultimately, the ISFD design allowed the steam turbine to run at full load and generate maximum power for the end user.

Solving the Challenge

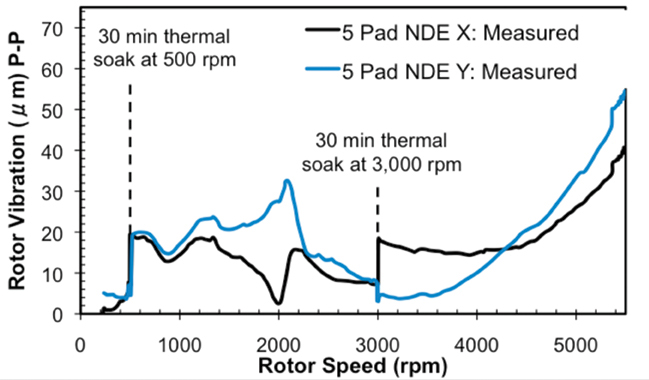

The steam turbine’s original 5-pad rocker pivot TPJ bearings were designed with asymmetrical oil film stiffness to try to accommodate the rotordynamics of the combined cycle system, but the rotor flexibility and destabilizing steam whirl forces resulted in a negatively damped system and, consequently, strong subsynchronous vibrations at about 30 Hz (see Figure 2). In contrast, bearings with ISFD technology provide low stiffness and high effective damping to maximize the damping ratio and eliminate subsynchronous vibrations.

The ISFD design is manufactured through electrical discharge machining (EDM). Integral “S” shape springs connect an outer and inner ring, and a squeeze film damper land extends between each set of springs. Bearing pads are housed in the inner ring. The unique design allows for high-precision control of concentricity, stiffness and rotor positioning, and it produces superior damping effectiveness by separating stiffness from damping.

While a conventional squeeze film damper (SFD) experiences a dynamic stiffness from the damper film that is dependent on amplitude and frequency, in the ISFD design, the stiffness is defined only by the springs. This allows for good predictability and precise placement of critical speeds and rotor modes, regardless of vibration amplitudes and frequencies.

ISFD damping is controlled by flow resistance at the oil supply nozzle and end seals. Whereas damping in a conventional SFD is generated by squeezing in the damper film and governed by circumferential film flow, the segmented ISFD design prevents circumferential flow and absorbs energy through the piston/dashpot effect.

Both the stiffness and the damping of the ISFD design are optimized for the application through a rigorous rotordynamic analysis. For the steam turbine, since steam whirl was one of the root causes of the subsynchronous vibrations, the analysis of the ISFD solution paid careful attention to modeling destabilizing seal forces and stage forces. A damped eigenvalue analysis without those forces showed a better stability margin by a factor of 12 with the ISFD design compared to the original bearings. With the destabilizing forces, the ISFD solution maintained a high stability margin (see Figure 3). The combination of low stiffness and optimum damping at the bearing support is the key in transforming bending modes to more rigid body modes and improving the overall stability and damping ratio of the rotor/bearing system.

Field Data

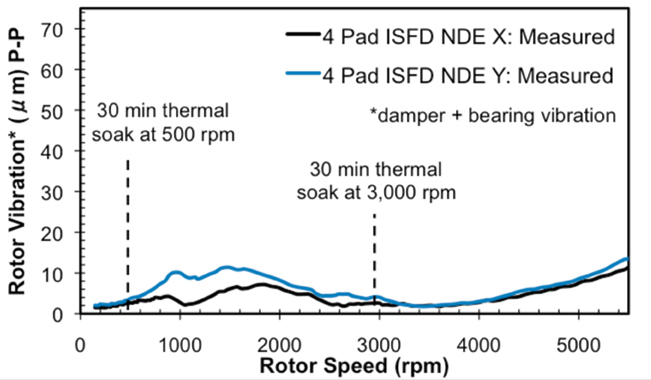

Field vibration data after the installation of the bearings with ISFD technology supported the rotordynamic analysis, showing a well-damped system. The ISFD design significantly reduced the synchronous vibrations and eliminated vibration increases and fluctuations, even during thermal transient at startup (see Figure 4).

Figure 4: Field vibration measurements of the synchronous response: original 5-pad TPJ bearing (left) versus 4-pad TPJ bearing with ISFD technology (right)

Furthermore, the subsynchronous vibration spikes experienced at the initial commissioning (Figure 2) were eliminated with the use of the ISFD design (see Figure 5). The larger stability margin provided by the bearings with ISFD technology freed the system from significant subsynchronous vibrations and enabled full-speed, full-power operation of the turbine.

Versatility

Flexible rotors in high-speed and high-pressure applications are especially susceptible to rotordynamic instabilities and high amplification factors through critical speed transitions. Whether the application is an integrally geared compressor, centrifugal compressor, steam turbine or generator, the ISFD bearing-damper solution can be engineered to a specific support stiffness and damping to maximize the ratio of energy transmitted to the bearing locations and significantly improve the stability of the system.