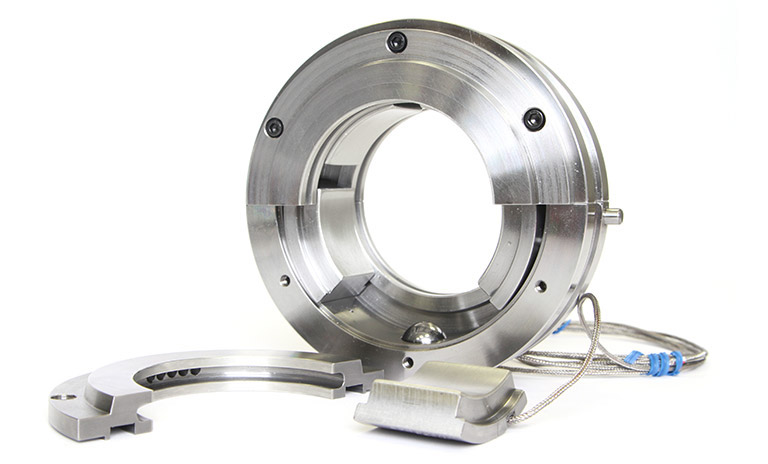

Tilt Pad Journal Bearings

Tilt pad journal bearings provide an inherently stable design for rotating machinery.

Bearings Plus provides several pad pivot types and geometries to increase load capacity, accommodate misalignment and optimize dynamic performance of the machine.

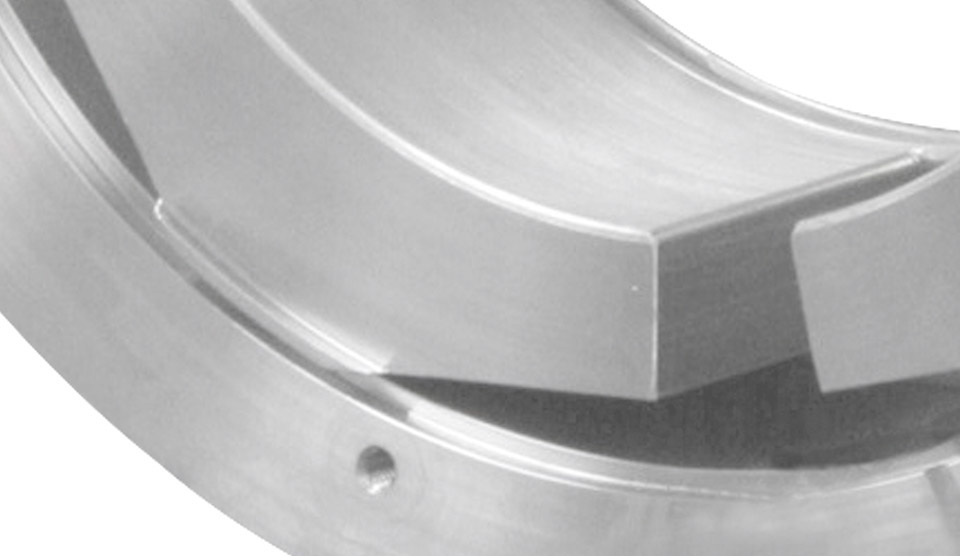

Two of the most common tilt pad designs are rocker back pads and ball and socket pads. Rocker back tilt pads use a line contact to allow the pad to tilt, while ball and socket pads have a spherical surface contact. In both instances, pads are retained in a shell (or housing) and held in place by end plates.

Rocker Pivots vs Ball and Socket Pivots

Rocker pivots typically cover the full axial length of a bearing pad, providing greater stiffness than the ball and socket pivot. The pads, however, do not allow any axial tilting motion, and can lead to high pivot stresses if there is any misalignment.

The full surface contact of the spherical ball and socket pivot reduces stress on the pivot compared to tilt pad designs using a point or line contact, and also allows tilting motion in all directions.

Optimization

Bearings Plus can further optimize tilt pad journal bearings via the number of pads, pad arc, pad offset, preload, clearance, lubrication type and material selection.

Flexure Pivot® tilt pad journal bearings, in which the pad and pivot are integral to the bearing shell, are available as a high-stability option.

Technical Data

- Sizes from 9.5 mm (0.375″) to more than 910 mm (36″)

- Surface speeds up to 120 m/sec (400 ft/sec)

- Unit loads up to 3.1 MPa (450 psi)

- Variety of pivot designs

- Instrumentation, such as temperature sensors

Downloads

Related Products

Bearing Repairs

Bearings Plus provides complete replacements, repair and rebabbitting for tilt pad and fixed profile bearings, all backed by robust quality inspections.