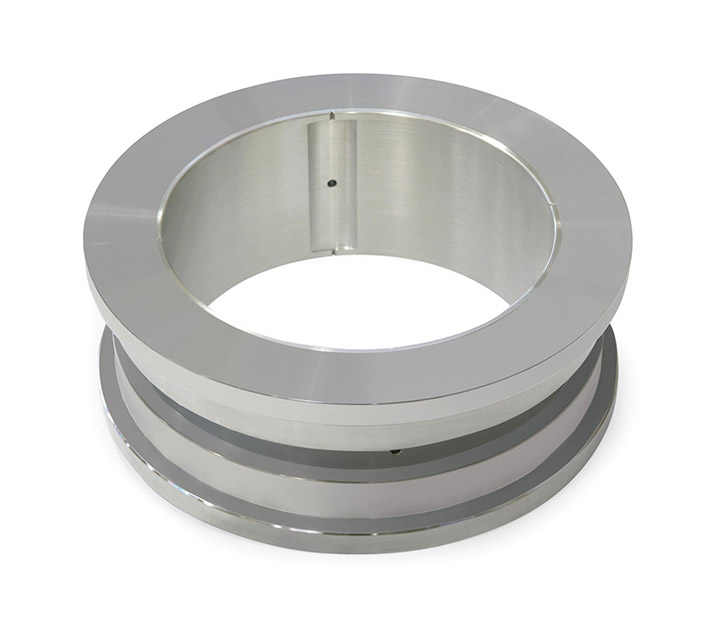

Sleeve Bearings

Sleeve bearings are a simple and economic design with wide application in rotating machinery.

These fixed geometry bearings come in several configurations to handle varying application needs for load capacity, rotating load, stiffness, damping, and rotordynamic stability (resistance to whirl).

The addition of grooves can reduce destabilizing effects due to fluid rotation, while alterations to the circular geometry provide additional stability gains.

Design variables to optimize performance include lobe geometry, number of lobes, bearing material, and lubrication. Lubrication may be pressure fed or self-lubrication, the latter typically with an oil ring.

Sleeve Bearing Geometries

Plain Sleeve

Plain sleeve bearings are cylindrical bearings, typically horizontally split and with the lubricant supplied through axial grooves located at the horizontal joint.

Multi-lobe

Most multi-lobe bearing designs have three or four lobes, which can be centered for bi-directional rotation or offset for uni-directional rotation. Specialized designs may also have plain segments in the loaded region and tapered segments in the remaining areas. The multi-lobe bearing provides increased stability over plain sleeve bearings. They are typically used in high-speed machinery with light rotors.

Lemon Bore

A specific kind of multi-lobe bearing, the lemon bore bearing has two large lobes offset about the center, giving them an elliptical shape. The vertical clearance is slightly smaller than the horizontal clearance. The design suppresses oil whirl with a vertical preload and can improve stiffness and damping over a plain sleeve bearing.

Pressure Dam

One of the most stable fixed geometry bearings available, the pressure dam bearing has a characteristic relief track, machined into the upper (unloaded) half, that comes to an abrupt end (pressure dam) to create an artificial load on the journal. This artificial load forces the shaft into a more eccentric position, resulting in greater stability.

Offset Half

The upper and lower halves of an offset half bearing are displaced transverse to the shafts axis for greater stability than plain sleeve bearings.

Technical Data

- Sizes from 9.5 mm (0.375″) to over 910 mm (36″)

- Surface speeds up to 60 m/sec (200 ft/sec)

- Unit loads up to 2.8 MPa (400 psi)

- CNC manufacturing of spherical OD bearings